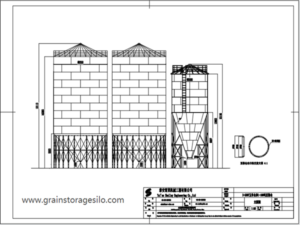

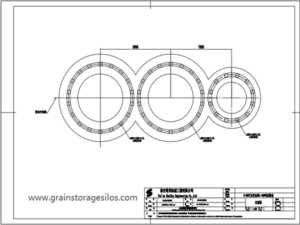

This is a hopper bottom steel silo project for a livestock farm in Hebei province.2 sets 500T corn storage silos and 1 set 100T bean pulp storage silo.

There is a flange connection at bottom of 100T bean pulp’s silo,in order to connect with four axis screw conveyor.

And we designed 70°corner cone bottom silo for bean pulp,to make sure bean pulp goes out smoothly.

2x500T galvanized grain silo specification in this system

Model:TCZK08210

Diameter:8.2m

Volume:708m3

Eave height:16.203m

Total height:18.113m

Hopper bottom silo rings:10 rings

Silo bottom angle:45°

Zinc coated:275g/m2

100T galvanized grain silo specification in this system

Silo model:TCZK04505

Volume:121.13m3

Diameter:4.50m

Eave height:10.48m

Total height:11.58m

Zinc coated:275g/m2

Hopper bottom silos (also called cone bottom silos, hopper bottom storage bins, hopper bins) are the steel silos with a cone bottom. Hopper bottom silos are erected on the supporting structure to make the delicate products unloading easily through gravity. Hopper silos have a smooth wall hopper transition with no steps or flanges to offer the cleanest product discharge from the silo. The stored products inside the silo are isolated from the ground, thereby preventing humidity and allowing the interconnection of silos through tapes, facilitating perfect extraction or dosage.

Tencent Weibo

Tencent Weibo Sina Weibo

Sina Weibo Wechat

Wechat Sales: 14th floor, Yingtai culture writing center, Daiyue District, Tai'an City, Shandong Province, China

Sales: 14th floor, Yingtai culture writing center, Daiyue District, Tai'an City, Shandong Province, China  Factory: 888 Yitianmen Street, Daiyue District, Tai'an City, Shandong Province, China

Factory: 888 Yitianmen Street, Daiyue District, Tai'an City, Shandong Province, China Email:shelley@cnshelley.com

Email:shelley@cnshelley.com Copyright 2017-2018 Taian Shelley Engineering Co., Ltd. Cnshelley.com. All rights reserved.

Copyright 2017-2018 Taian Shelley Engineering Co., Ltd. Cnshelley.com. All rights reserved.